User manual for Saratov freezer models 153, 154, 170, 171, 172

Руководство / инструкция

Saratov Freezer Operating Manual

LLC “SEPO-ZEM”

410040, Russia, Saratov, 50 Let Oktyabrya Avenue, Lenin Square

ATTENTION CUSTOMERS!

When purchasing the freezer in a store, please check:

– absence of mechanical damage;

– operability and completeness;

– presence of the date of sale and the store stamp in the detachable coupons of the warranty card.

The owner shall install and put the freezer into operation independently, following Sections 1, 4, 6, 7, and 8 of the Operating Manual (OM) and complying with safety regulations.

Due to ongoing design improvements, your freezer may have minor differences not reflected in the manual.

FREEZER MODELS

«Саратов-153» МКШ-135

«Саратов-154» МШ-90

«Саратов-170» МКШ-180

«Саратов-171» МКШ-135

«Саратов-172» МШ-90

.

1 General Instructions

1.1 The freezer is intended for freezing fresh food products and for their long-term storage under domestic conditions. The freezer shall be operated in rooms with an ambient temperature from +16°C to +32°C and a relative air humidity not exceeding 70%. At temperatures above +32°C, continuous compressor operation in the “storage” mode is possible, which is undesirable. Before using the freezer, carefully read the rules provided in this manual.

1.2 During operation of the freezer, the owner must prevent:

– operation of the freezer on any type of moving transport, as well as in rental points and public places related to entrepreneurial activity;

– non-compliance with installation and operating rules;

– negligence during storage and transportation;

– use of self-made electrical devices;

– repair of the freezer by persons not authorized to perform warranty repairs;

– violation of the seals on the starting-protection relay and the temperature sensor-relay;

– damage to the freezer’s wiring;

– connection of the freezer to an electrical network with voltage fluctuations above 242 V and below 198 V.

❗👉➨ Note – The freezer may be operated in organizations provided that a responsible person is appointed to ensure compliance with the operating rules.

2 Technical Requirements

Table 1

| Technical Specification | Model | ||||

| “Saratov-154” | “Saratov-172” | “Saratov-153” | “Saratov-171” | “Saratov-170” | |

| 1 Overall dimensions, mm height width depth |

880 480 600 |

880 480 600 |

1145 480 600 |

1145 480 600 |

1470 480 600 |

| 2 Total shelf area, m? | 0.43 | 0.43 | 0.64 | 0.64 | 1.02 |

| 3 Total freezer compartment volume, dm? | 94 | 94 | 135 | 135 | 180 |

| 4 Usable freezer compartment volume, dm? | 60 | 60 | 85 | 85 | 122 |

| 5 Rated supply voltage, V | 220 | 220 | 220 | 220 | 220 |

| 6 Frequency, Hz | 50 | 50 | 50 | 50 | 50 |

| 7 Power consumption, kW | 0.135 | 0.135 | 0.135 | 0.135 | 0.135 |

| 8 **Daily energy consumption at an ambient temperature of +25°C and a freezer compartment temperature of ?18°C, kWh, not more than | 0.9 | 0.9 | 0.99 | 0.99 | 1.1 |

| 9 Energy efficiency class according to GOST R 51388-99 | C | C | C | C | C |

| 10 **Temperature in the freezer compartment in storage mode, °C, not higher than | ?18 | ?18 | ?18* | ?18* | ?18* |

| 11 Freezing capacity, kg/day, not less than | 9 | 9 | 10 | 10 | 12 |

| 12 Weight of freezer without packaging, kg, not more than | 35 | 32 | 40 | 36 | 50 |

| 13 Silver content, g | 1.4339 | 1.4339 | 1.4339 | 1.4339 | 1.4339 |

| 14 Content of non-ferrous metals, kg: aluminum copper | 2.18 1.2 | 2.18 1.2 | 2.6 1.2 | 2.6 1.2 | 3.89 1.2 |

*In the upper compartment, a temperature of ?12°C is permissible, not more.

**Objective evaluation of temperature and energy consumption is carried out under laboratory conditions in accordance with GOST 16317-87.

..

3 Scope of Supply

The delivery set includes a packaged freezer with accessories according to Table 2, the “Operating Manual,” the “Warranty Card,” and the energy efficiency label of the refrigeration appliance.

Table 2

| Name | Quantity, pcs | ||||

| “Saratov-153” | “Saratov-154” | “Saratov-170” | “Saratov-171” | “Saratov-172” | |

| 1 Tray | 1 | 1 | 1 | 1 | 1 |

| 2 Lower container | 1 | 1 | 1 | 1 | 1 |

| 3 Panel (curtain) | - | - | - | 1 | 1 |

| 4 Container | 5 | 3 | 7 | 4 | 2 |

| 5 Berry container | 1 | 1 | 1 | 1 | 1 |

| 6 Ice tray | 1 | 1 | 1 | 1 | 1 |

❗👉➨ Note – The arrangement of the accessories is shown in Figures 1, 1a, and 1b.

4 Safety Requirements

4.1 The freezer is designed for use inside heated premises. Operation outside such premises is not permitted.

4.2 The freezer is not intended for use by persons (including children) with reduced physical, sensory, or mental capabilities, or lacking experience or knowledge, unless they are supervised or instructed on the use of the freezer by a person responsible for their safety. Children must be supervised to prevent them from playing with the freezer.

4.3 Before connecting the freezer to the power supply, check the plug and cord for any damage to the insulation.

4.4 If the power cord is damaged, it must be replaced by the manufacturer, service organization, or similarly qualified personnel in order to avoid hazards.

4.5 Freezers are manufactured with electric protection class “0” – without a grounding device, or class “1” – where the plug and internal components are electrically connected to the ground.

4.6 If the socket in your home does not match the freezer plug, you must contact a qualified electrician to install a suitable socket.

❗👉➨ WARNING!! A CLASS “1” PROTECTION FREEZER MUST BE CONNECTED ONLY TO A POWER SUPPLY WITH GROUNDING.

4.7 If the freezer is to be installed in a room without a residual-current device (RCD), it must be operated with an RCD having parameters no worse than the following: rated voltage range from 220 to 240 V, alternating current with a frequency of 50 Hz, rated load power not less than 1.3 kVA, tripping time at a leakage current of up to 30 mA – no more than 1 second. The RCD installation must be performed by a repair service technician for an additional fee.

4.8 If signs of wiring short-circuit to the body appear (tingling sensation when touching metal parts), disconnect the freezer from the mains and call a technician to fix the fault.

4.9 IT IS PROHIBITED TO TOUCH THE OPERATING FREEZER AND DEVICES WITH NATURAL GROUNDING (GAS STOVES, HEATING RADIATORS, WATER TAPS, ETC.) SIMULTANEOUSLY.

4.10 Disconnect the freezer from the mains when: cleaning it inside and outside, moving it to another location, washing the floor beneath it, or repairing faults.

4.11 Prevent liquids from entering the control devices. If moisture or steam reaches the control devices or wiring components, immediately disconnect the freezer from the power supply. Restarting is allowed only after ensuring safe operating conditions.

4.12 OPERATION OF THE FREEZER IS PROHIBITED IN PREMISES:

– WITH A CHEMICALLY ACTIVE ENVIRONMENT (WHERE DEPOSITS FORM OR ARE PRESENT THAT CAN CAUSE DAMAGE TO ELECTRICAL PARTS);

– WITH EXCESSIVE HUMIDITY (WHEN CEILINGS, WALLS, AND OBJECTS IN THE ROOM ARE COVERED WITH MOISTURE), OR WITH CONDUCTIVE DUST;

– WITH CONDUCTIVE FLOORS (METALLIC, EARTH, REINFORCED CONCRETE).

4.13 FOR FIRE SAFETY PURPOSES, IT IS PROHIBITED TO USE HOMEMADE ADAPTERS, MULTI-SOCKET EXTENSIONS (WITH TWO OR MORE OUTLETS), OR EXTENSION CORDS TO CONNECT THE FREEZER TO THE POWER SUPPLY.

4.14 TO ENSURE ELECTRICAL AND FIRE SAFETY, IT IS PROHIBITED TO OPERATE THE FREEZER BEYOND ITS SPECIFIED SERVICE LIFE (10 YEARS) WITHOUT TECHNICAL INSPECTION.

4.15 The freezer complies with the requirements of the Technical Regulations of the Customs Union. Certificate of Conformity TC RU C-RU.AЮ17.B.00091, valid until 09.03.2020, issued by LLC “Saratov CSM” (address: 410065, Saratov, Tverskaya St., 51A).

5 Saratov Freezer Design

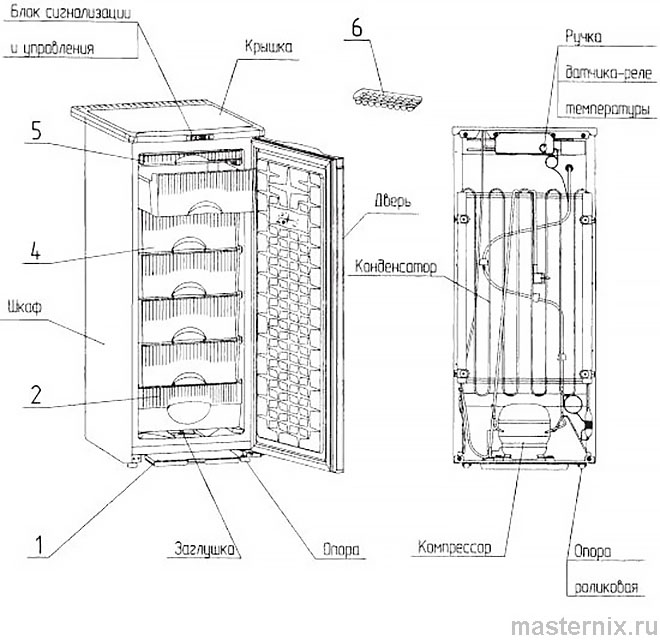

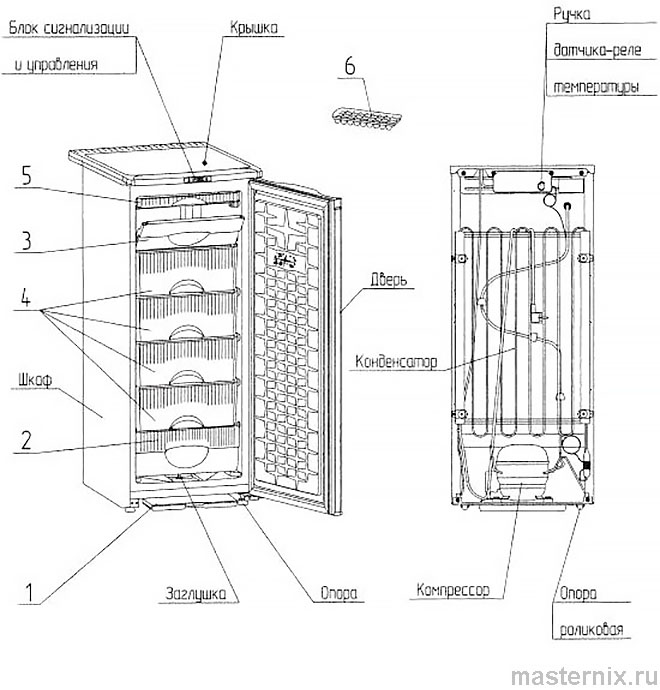

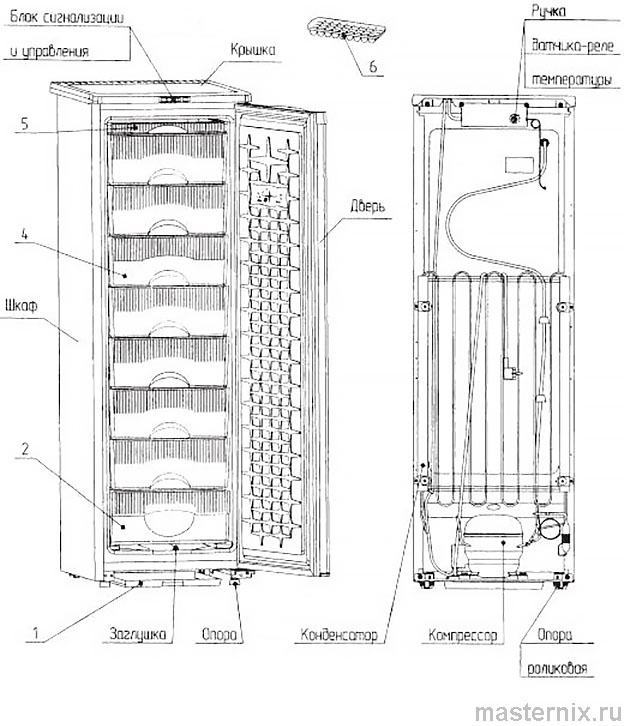

5.1 The main components and parts of the freezer are shown in Figures 1, 1a, and 1b.

Figure 1 – Design of “Saratov-153” and “Saratov-154” freezers

1 – tray;

2 – lower container;

4 – container;

5 – berry container;

6 – ice tray

Figure 1a – Design of “Saratov-171” and “Saratov-172” freezers

1 – tray;

2 – lower container;

3 – curtain;

4 – container;

5 – berry container;

6 – ice tray

Figure 1b – Design of “Saratov-170” freezer

1 – tray;

2 – lower container;

4 – container;

5 – berry container;

6 – ice tray

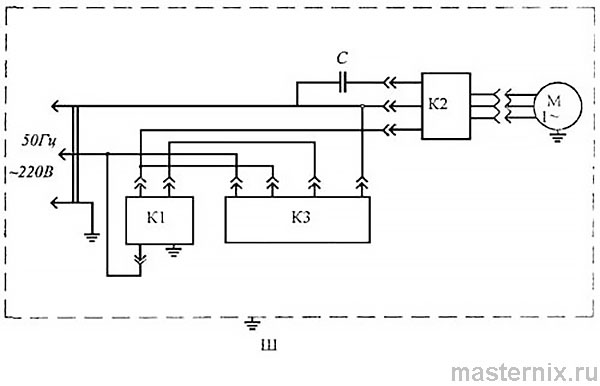

5.2 The freezer is manufactured with electric protection class “0” – without a grounding device, or class “1” – with a grounding device (Figure 2).

Figure 2 – Wiring diagram

K1 – temperature sensor-relay;

K2 – starting-protection relay;

K3 – alarm and control unit;

M – compressor;

Sh – cabinet;

C – capacitor; ⏚ – grounding for class 1 protection freezers

❗👉➨ Note – The capacitor “C” may be absent in the product.

5.3 On the front surface of the top panel, there is an alarm and control unit, which includes:

– rocker switch (2);

– mode selector for freezing and storage with three indicator lights:

red (emergency mode) (4),

yellow (freezing mode) (1),

green (storage mode) (3).

When the freezer is first switched on, the red light (4) turns on until the freezer reaches operating temperature. Once it goes out, products can be loaded. During operation, this light may also come on in case of a malfunction. The freezing mode (1) is recommended to be switched on after loading new unfrozen products into the freezer.

On the rear panel of the freezer compartment, there is a handle for the temperature sensor-relay.

5.4 The temperature mode is set using the temperature sensor-relay handle. The manufacturer adjusts the handle position to ensure compliance with technical parameters.

5.5 The freezer allows for the door to be re-hinged for left-hand opening. This operation is performed by a service technician for an additional fee.

6 Preparation for Operation

6.1 Before using the freezer, perform the following steps:

– remove all packaging materials from the freezer;

– place the freezer away from heat sources (stoves, ovens, fireplaces) in a well-ventilated location. Avoid exposure to direct sunlight. Ensure that during operation the air supply to the ventilation openings is not blocked or restricted;

– to enable automatic door closing, tilt the freezer slightly (3 to 5 mm) toward the condenser (by adjusting the supports). For optimal performance, the freezer should be positioned on a level surface. After placing the freezer in position, adjust its alignment;

– wash, wipe, and air the freezer according to the “Maintenance” section;

– if the freezer has been brought in from a cold environment, it may only be switched on after being kept for at least 6 hours at room temperature.

6.2 Before connecting the freezer to the power supply, make sure that the voltage indicated on the plate on the rear wall of the freezer matches the mains voltage. After connecting the power cord to the socket, it should remain in a free (unstrained) position.

7 Operating Procedure

7.1 Connect the freezer to the power supply. The interval between repeated switch-ons must be at least 5 minutes.

7.2 Set the rocker switch on the alarm and control unit to the freezing mode. The yellow and red indicators will light up. In freezing mode, the compressor operates continuously.

Begin loading the freezer after the red indicator goes out (within approximately two hours after switching on). When loading products into the freezer, do not exceed the freezing capacity, as exceeding it increases freezing time and reduces the quality of the frozen products. If fewer products are loaded, the freezing time will be shorter.

7.3 After the freezing time has elapsed, set the rocker switch to the storage mode. The yellow indicator will turn off, and the green indicator will light up. The freezer compartment will automatically maintain the temperature specified in Section 2.

7.4 The red indicator lighting up again indicates a violation of the storage mode (loading more products than recommended or a malfunction).

The freezer can be used for freezing and long-term storage of meat products, fish, bread and bakery products, vegetables, fruits, and berries (except citrus fruits).

7.5 When freezing and storing products, it is recommended to:

– place only fresh products into the freezer, packed in portions suitable for your needs and always wrapped in polyethylene film, aluminum foil, or other moisture- and odor-proof materials;

– follow the storage periods indicated on the door panel;

– avoid placing liquid products in glass containers;

– store products only in containers.

7.6 To prepare ice, fill the ice tray with water and place it in one of the freezer containers until frozen.

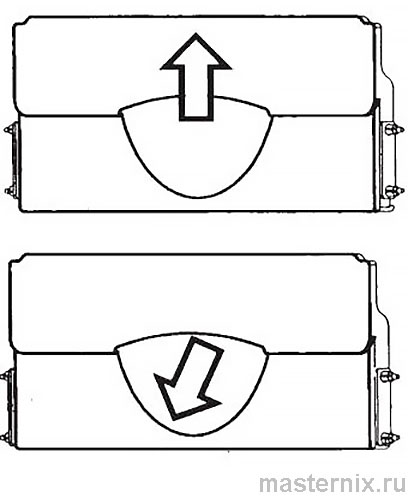

7.7 To open the panel (curtain) of the freezer compartment (models “Saratov-171,” “Saratov-172”), lift the panel upward and then pull it toward you as shown in Figure 3.

Figure 3 – Opening the panel-curtain

7.8 To prevent condensation of moisture on the lower front surface of the cabinet, the design includes heating of this area. During operation, this surface may become warm, which is normal.

During periods of high relative humidity (above 70%) or low ambient temperatures (below +16°C), moisture may condense on the side surfaces of the freezer cabinet. This is not a defect and does not affect the performance characteristics of the freezer.

7.9 You may hear clicks from the temperature sensor-relay, cracking sounds from temperature fluctuations, and gurgling sounds from the movement of refrigerant through the tubes. These sounds are functional and do not affect the operation or reliability of the freezer.

7.10 During operation, the compressor surface may heat up to 90°C.

8 Maintenance

8.1 Long-term and trouble-free operation of the freezer depends on correct usage and proper care. During use, frost will form on the evaporator walls, and defrosting is recommended at least once or twice a year. If a small layer of frost (2–3 mm thick) forms on the evaporator, especially in its upper part, it should be removed with a plastic or wooden spatula without waiting for the scheduled defrosting of the freezer. If a thick layer of frost forms, preventing the upper container from being pulled out and it cannot be removed with a spatula, defrosting must be performed.

8.2 Cleaning should be carried out as follows:

– disconnect the freezer from the mains;

– remove products from the freezer; wrap frozen products in several layers of paper and place them in a cool location;

– remove the plug and place tray 1 (Figures 1, 1a, 1b) under the drain opening to collect defrost water;

– to speed up defrosting, keep the freezer door open. It is prohibited to use electric heaters for defrosting. Do not use sharp or metal objects to remove frost, as they may damage the walls;

– after removing the frost, wipe the evaporator with a soft cloth moistened in warm water and dry it thoroughly. Wipe the outer surfaces of the cabinet and the door with a soft cloth moistened in warm, slightly soapy water. The surface of the freezer compartment and the inner door panel may be wiped with a cloth moistened in a baking soda solution (1 tablespoon per 1 liter of water). When cleaning the inner door panel, do not allow water to seep behind the door seal. Dry the freezer thoroughly with a soft cloth. Do not use powders or pastes for cleaning. Replace the plug in its original position. At least once every six months, clean the condenser of dust with a soft brush or vacuum cleaner and wash the tray. Prevent foreign objects from entering the condenser.

9 Storage and Transportation Rules

9.1 The freezer may be switched off for any length of time. To do so, disconnect it from the mains, wash it thoroughly, and dry it completely; keep the door slightly open.

9.2 Transportation of the freezer is permitted only in an upright position, ensuring protection from damage.

9.3 Store the freezer in its packaging in enclosed, naturally ventilated premises with a relative humidity not exceeding 70%.

10 List of Possible Malfunctions and Troubleshooting Methods

Table 3

| Possible malfunction | Probable cause | Remedy |

| 1 Increased noise, rattling | Unstable position of the freezer. Refrigeration system piping is touching the freezer cabinet |

Install the freezer according to this manual (clause 6.1). Eliminate contact by carefully bending the piping away |

| 2 Freezer connected to mains does not operate | No voltage in the mains. No contact between the plug and socket |

Check for voltage. Ensure proper contact between plug and socket |

| 3 Odor appears in the freezer compartment | Irregular or insufficient cleaning of the freezer compartment. Long-term storage of the freezer switched off with the door tightly closed. Storage of spoiled products | Thoroughly clean the freezer compartment and air the freezer for 3–4 hours |

| 4 Moisture forms on the freezer cabinet surface | The freezer is operated in a room with relative humidity above 70% or ambient temperature below +16°C | This is normal in a humid environment. Remove moisture with a dry towel |

❗👉➨ Notes:

1 Partial absence of frost on the evaporator is not a defect.

2 In case of other malfunctions, contact a specialized service workshop.

11 Warranty Obligations

11.1 The warranty period for the freezer is 3 years within the territory of Russia and 1 year outside the Russian Federation from the date of sale through the retail network. If the date of sale cannot be determined, the warranty period starts from the date of manufacture.

Transportation of the freezer for repair, its repair, and return to the owner after repair shall be carried out by the organization performing the warranty repair.

During the warranty period, the manufacturer (seller) is responsible for freezer malfunctions in the scope and according to the procedure established by the Law of the Russian Federation “On Protection of Consumer Rights.”

❗👉➨ Note – If the consumer violates transportation, storage, installation, and operating rules, the product is not subject to warranty repair if this is proven by the manufacturer (seller).

11.2 A warranty card is included with each freezer.

12 Disposal

12.1 Upon expiration of the service life (10 years), the consumer must contact a service workshop for technical inspection of the freezer to ensure electrical and fire safety.

For continued operation, such inspection should be carried out at least once every two years.

12.2 If further operation of the freezer is not possible, the consumer must render it unusable as follows:

– unplug the freezer and cut off the power cord;

– the compressor, refrigeration unit, starting-protection relay, and wiring may be disposed of as ferrous and non-ferrous metal scrap;

– the freezer cabinet and door must be disposed of in landfills for household and industrial waste in accordance with the rules and requirements set by local authorities.

Burning the insulation of the freezer cabinet and door is strictly prohibited due to the release of toxic substances during combustion.